Leaks

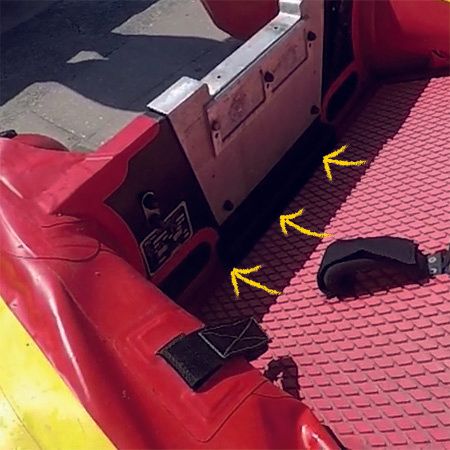

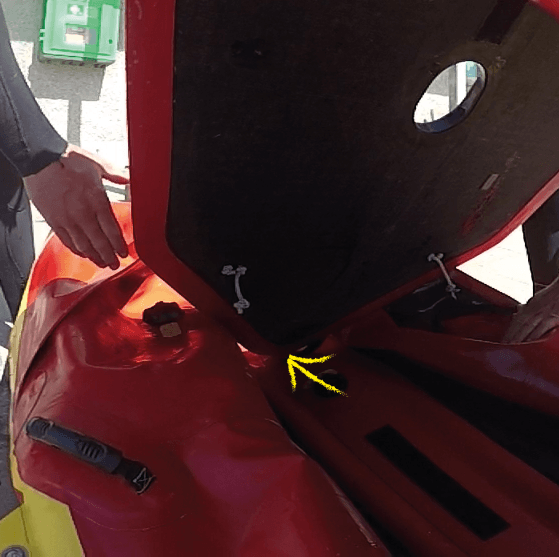

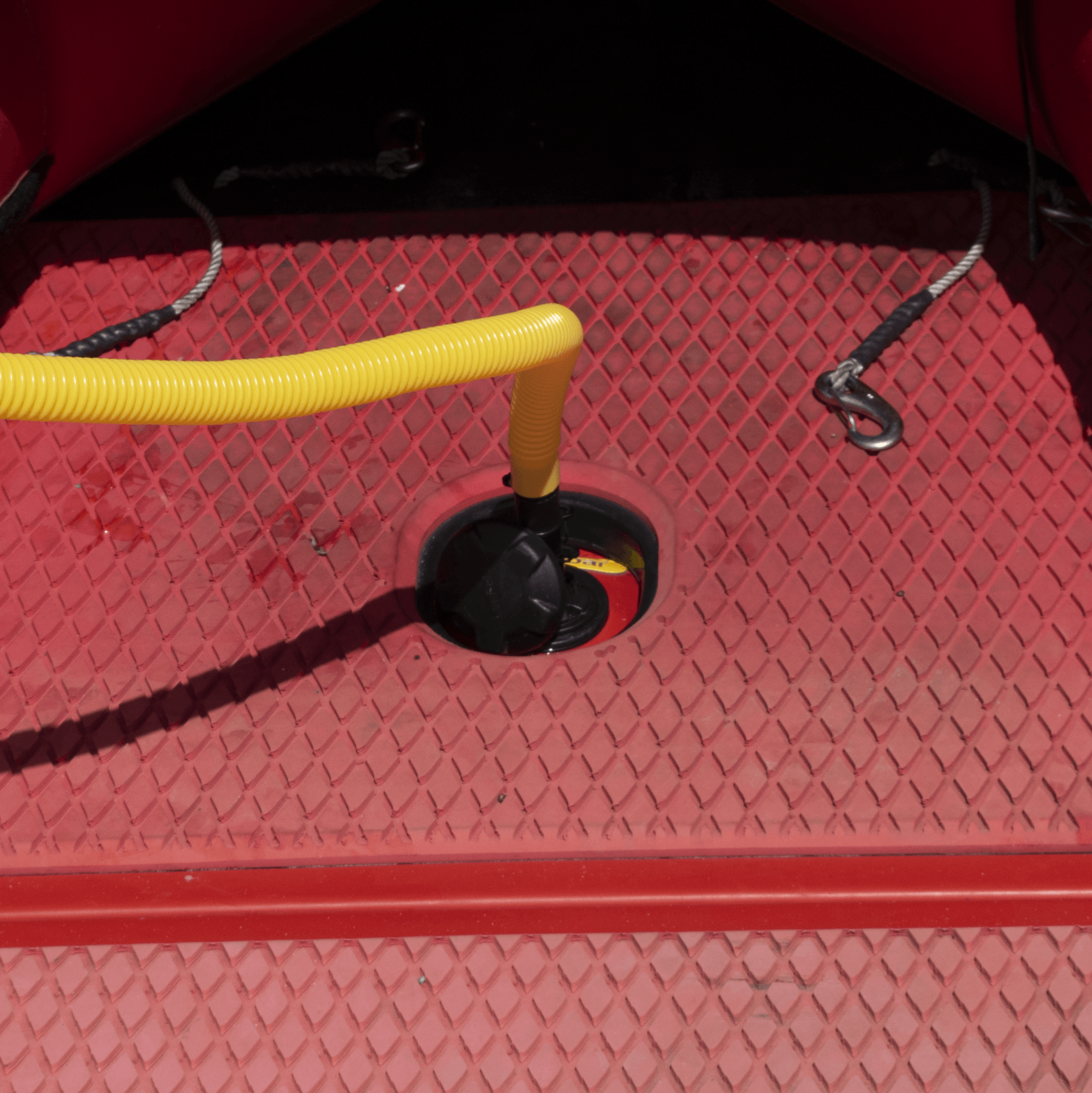

Potentially there are two main issues that can occur with a leaking IRB that will require maintenance. The first is a defective inflation valve that results in slow leaks and a loss of sponson or keel pressure (in the case of soft hull IRB’s). The second is damage to the ‘Hyperlon’ fabric.

A dirty valve should be first washed out with water to clear sand and dirt and the IRB reinflated.

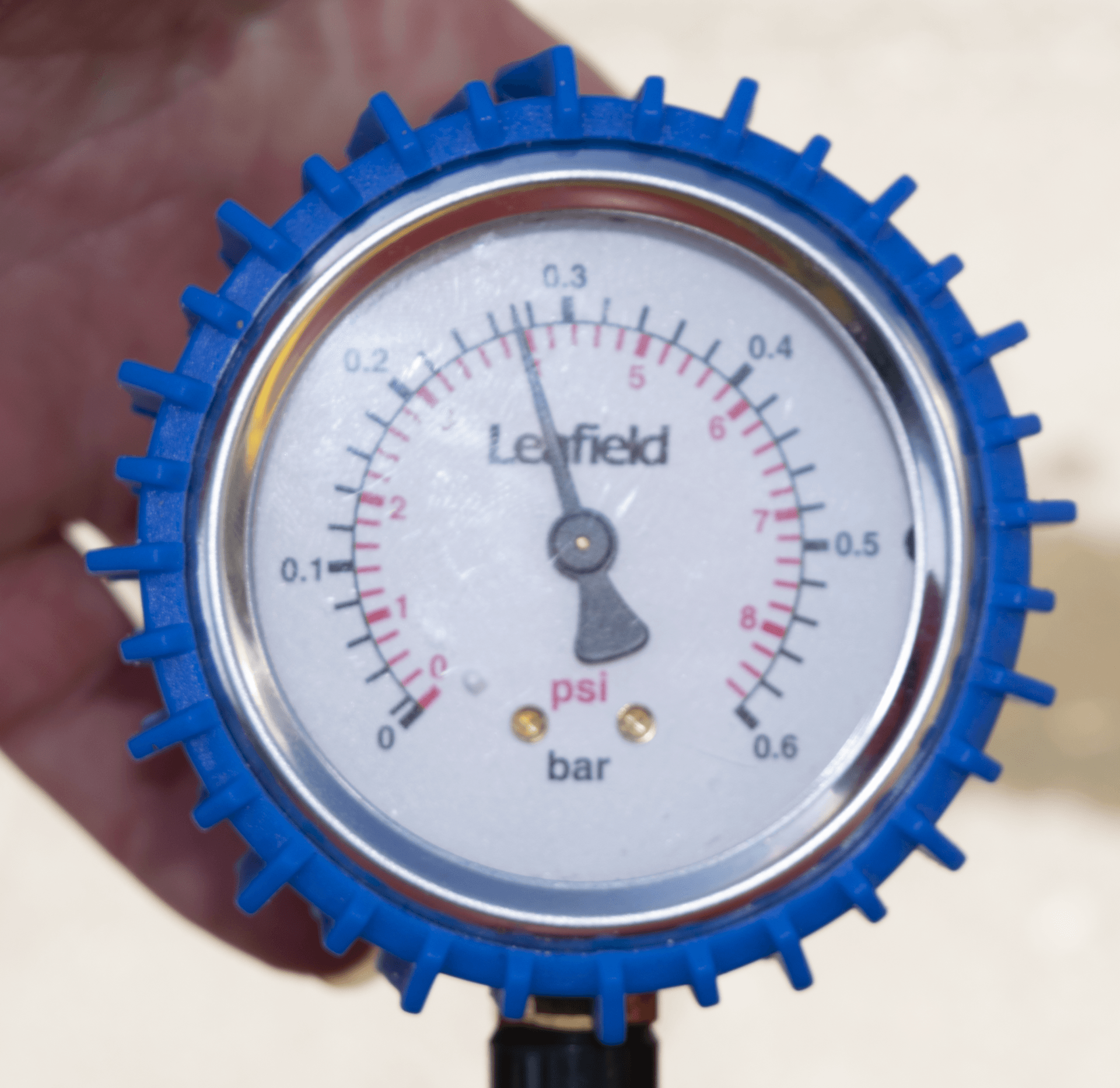

Then using a pressure guage check that inflation remains constant. Check again at the end of use to ensure integrity of the valve.

If the pressure is still reducing the sponson or keel may be punctured.